Metal Material

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Exploring the Accuracy of XRF Guns: How Precise Are They for Metal Analysis?

X-ray fluorescence (XRF) guns have become indispensable tools for metal analysis, providing quick, non-destructive insights into the composition of materials. But how accurate are these devices, and what should users consider to ensure reliable results?

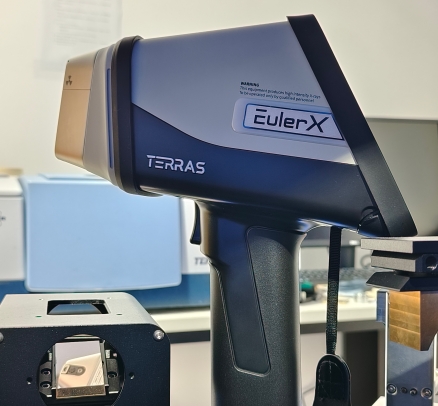

Terras EulerX900 Handheld Alloy Analyzer

Understanding XRF Technology

XRF guns operate by directing X-rays at a sample, which excites the atoms within the material. These excited atoms emit fluorescent X-rays, which are then detected and analyzed to determine the elements present and their concentrations. The method’s non-destructive nature and rapid results make it an attractive choice for many applications.

Factors Influencing Accuracy

Calibration and Calibration Standards: Regular calibration with certified standards is essential for accurate measurements. XRF guns must be recalibrated periodically to maintain precision, and the standards used should closely match the sample matrix.

Sample Preparation: Proper sample preparation is crucial. Contaminants, inconsistent surface conditions, or non-uniform samples can lead to inaccurate readings. For optimal results, ensure samples are clean, flat, and representative of the material being analyzed.

Elemental Concentration and Matrix Effects: The concentration of elements and the material's matrix can affect accuracy. High levels of certain elements might cause interferences, while the presence of a complex matrix can alter the fluorescence signal. Advanced XRF models with matrix correction capabilities can help mitigate these effects.

Instrument Quality and Features: The accuracy of an XRF gun is also dependent on its quality. High-end models with advanced detectors and X-ray tubes provide better resolution and precision. Features such as improved software algorithms and calibration capabilities enhance accuracy.

Case Studies and Applications

In industries such as metallurgy, recycling, and manufacturing, XRF guns have proven effective for quality control and compliance testing. For instance, in recycling facilities, XRF guns quickly identify and sort metals, ensuring proper recycling processes and material recovery. In manufacturing, they help verify alloy compositions to meet specifications.

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. The applications of the EulerX 900 handheld are extensive, covering not only solids but also liquids and powders. The X-ray technique preserves the integrity of the samples, unlike destructive testing methods.

Terras EulerX900 Handheld Alloy Analyzer

Conclusion

XRF guns are a reliable tool for metal analysis, offering high precision when used correctly. By understanding the factors affecting accuracy and maintaining proper calibration and sample preparation, users can leverage XRF technology to achieve dependable results. As XRF technology continues to advance, its role in material analysis will likely become even more prominent, providing valuable insights across various industries.

Join Us

Subscribe to our email list for updates & promotions.