Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Is Spektrometr XRF the Future of Non-Destructive Testing?

Non-destructive testing (NDT) is a critical field in industries like manufacturing, construction, aerospace, and archaeology. It allows professionals to assess the integrity of materials and structures without causing any damage. One of the key technologies in this area is X-ray fluorescence (XRF), a technique that has been gaining momentum due to its precision, efficiency, and versatility. In this article, we will explore how XRF works, its advantages, and why it might be considered the future of non-destructive testing.

What is XRF?

X-ray fluorescence (XRF) is a powerful analytical technique used to determine the elemental composition of materials. In the XRF process, a material is exposed to high-energy X-rays, causing the atoms in the material to emit secondary (or fluorescent) X-rays. The energy levels of these emitted X-rays are unique to the elements in the material, allowing for an in-depth analysis of its composition.

XRF spectrometers are often used to identify metals, alloys, polymers, and even the composition of soil or sediments. The data collected can tell you about the types and quantities of elements present, which is invaluable for quality control, material analysis, and regulatory compliance.

Why XRF is Gaining Popularity in NDT

Non-Destructive Nature:

XRF allows for fast and non-invasive analysis. Unlike traditional methods like chemical sampling or destructive testing, XRF preserves the material being tested, making it ideal for applications where the sample must remain intact.

Versatility:

One of the main advantages of XRF is its ability to analyze a wide range of materials. Whether it's a metal alloy, a construction material, or even artwork, XRF can be adapted to suit different needs. It is particularly valuable in industries like aerospace, mining, and environmental science.

Accuracy and Precision:

XRF spectrometers provide highly accurate results, often with minimal sample preparation. The technology has advanced to the point where even trace amounts of elements can be detected, making it ideal for ensuring the quality and safety of products.

Portability:

Advances in portable XRF devices mean that testing can be done on-site, rather than requiring samples to be sent to a laboratory. This reduces downtime and transportation costs, which is especially valuable for industries that require real-time analysis.

Cost-Effectiveness:

Over time, XRF spectrometers have become more affordable, making them accessible to smaller companies and operations. The ability to quickly and accurately assess materials without the need for lab testing or destructive sampling makes it a cost-effective choice for many businesses.

Applications of XRF in Non-Destructive Testing

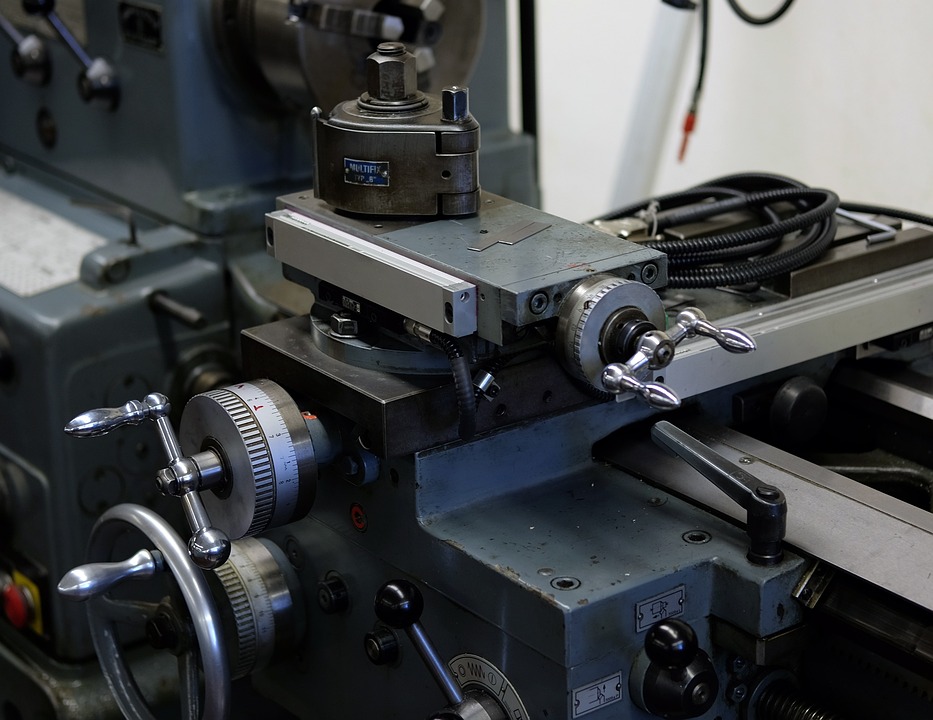

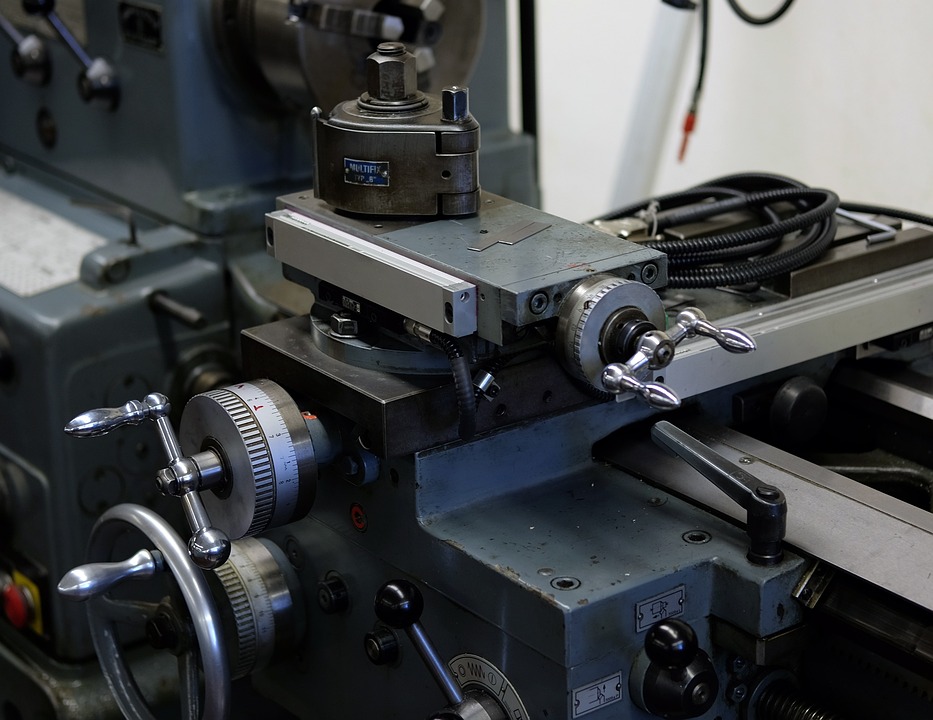

Metal Alloy Testing: In industries like manufacturing and aerospace, XRF is often used to analyze the composition of metal alloys, ensuring that they meet specified standards for strength, durability, and safety.

Environmental Monitoring: XRF is used in environmental science to analyze soil, water, and sediments for hazardous contaminants such as heavy metals. This makes it an invaluable tool for both environmental protection and regulatory compliance.

Archaeology and Art Conservation: XRF is also being used to analyze historical artifacts and artwork. By determining the elemental composition of these objects, researchers can gain insights into their origins and preservation, as well as detect potential forgeries or alterations.

Quality Control in Manufacturing: XRF is widely used in manufacturing settings to ensure that products meet required specifications. Whether it's checking the purity of raw materials or the composition of finished goods, XRF helps maintain product quality.

Terras PI900E Handheld Alloy Analyzer

Unlock instant, actionable insights into any metal with the powerful Pi900E. Designed for the real world, this portable spectrometer delivers non-destructive, lab-accurate results in seconds—directly on the production line, at the scrap yard, or in the field. Its robust build, simple touchscreen operation, and wireless connectivity empower your team to streamline QA, maximize recovery value, and ensure compliance effortlessly. Confidently analyze a vast spectrum from Mg to U and make critical decisions with data you can trust.

Is XRF the Future of NDT?

As industries continue to prioritize efficiency, accuracy, and sustainability, XRF technology shows great promise as a leading method for non-destructive testing. Its non-invasive nature, combined with its ability to provide quick, accurate results, makes it an attractive option for many different fields.

While it may not replace all forms of testing, it can certainly complement traditional methods and even replace some of them, especially in situations where non-destructive, real-time testing is critical.

Moreover, as technological advancements continue to improve the capabilities of XRF spectrometers—such as enhanced sensitivity and miniaturization—this tool is likely to become even more indispensable in industries across the board.

In conclusion, while XRF is already a powerful tool in the world of non-destructive testing, it is clear that its potential is far from fully realized. With continued innovation and refinement, XRF may well become the future of NDT, offering unmatched precision, portability, and ease of use.

Join Us

Subscribe to our email list for updates & promotions.