Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Understanding the Technology Behind X Ray Analyzers Available Online

X-ray analyzers are essential tools in various fields, including medical diagnostics, security, industrial inspections, and material science. These devices utilize X-ray radiation to capture images and analyze the internal structure of objects or materials. With the rise of e-commerce, many X-ray analyzers are now available for purchase online, offering convenient access to advanced technology. In this blog post, we'll explore the technology behind X-ray analyzers and highlight what to consider when purchasing one online.

What is an X-Ray Analyzer?

An X-ray analyzer is a device that uses X-ray radiation to examine the internal composition of materials without causing any harm or altering the object being studied. X-ray technology is based on the principle that different materials absorb or transmit X-rays at varying rates. The analyzer emits X-rays through an object, and detectors capture the resulting transmission or reflection patterns, which are then used to generate an image or a detailed analysis.

There are several types of X-ray analyzers, including:

X-ray Fluorescence (XRF) Analyzers - These are primarily used for analyzing the elemental composition of materials. When an X-ray beam strikes a material, the elements in the material emit fluorescent X-rays that are detected and analyzed.

X-ray Diffraction (XRD) Analyzers - Used for determining the crystalline structure of materials, XRD analyzers help identify phase compositions and molecular arrangements.

Computed Tomography (CT) Scanners - These are a more advanced form of X-ray analyzers, often used in medical diagnostics. They create detailed 3D images by taking multiple X-ray images from various angles.

Transmission X-ray Analyzers - These analyzers measure how much X-ray passes through a material, allowing for detailed imaging of the internal structures.

How X-Ray Analyzers Work

X-ray Generation: The first step involves generating X-rays. A high voltage is applied to an X-ray tube, which causes electrons to strike a target material (often tungsten), producing X-rays.

Interaction with Materials: The generated X-rays pass through or interact with the material being analyzed. Depending on the composition of the material, different wavelengths of X-rays will be absorbed or transmitted.

Detection: Detectors placed behind or around the material capture the transmitted or reflected X-rays. These detectors can be scintillation detectors, gas-filled detectors, or semiconductor detectors, depending on the type of analyzer.

Image Creation/Analysis: The data collected by the detectors is processed to generate an image or an analysis report. The image reveals the internal structure, and the analysis can provide detailed information about the material's composition.

Factors to Consider When Purchasing an X-Ray Analyzer Online

Purpose and Application: X-ray analyzers are available for various purposes, from medical use to industrial applications. Be sure to select a device that suits your specific needs. For instance, if you're working in materials science, an XRD or XRF analyzer may be more suitable. If you're focused on security or medical imaging, a CT scanner might be the better choice.

Resolution and Sensitivity: Different X-ray analyzers have varying resolutions and sensitivities. A higher resolution provides more detailed images or data, while increased sensitivity is important for detecting smaller quantities or minute variations in materials.

Software and Data Analysis: Modern X-ray analyzers come with software that helps users interpret the collected data. Look for a device with user-friendly software that can generate reports, visualize results, and make necessary adjustments.

Safety Features: Since X-rays involve radiation, safety is crucial. Make sure the analyzer comes with built-in safety features, such as shielding to prevent exposure, radiation alarms, and compliance with local safety regulations.

Terra In-line XRF Analyzer NewtonX

Cost and Warranty: X-ray analyzers can be expensive, so it's important to consider your budget. Additionally, check if the device comes with a warranty or customer support for troubleshooting.

Reviews and Ratings: Before purchasing, review customer feedback and ratings. These can provide insight into the reliability, ease of use, and customer service associated with the analyzer.

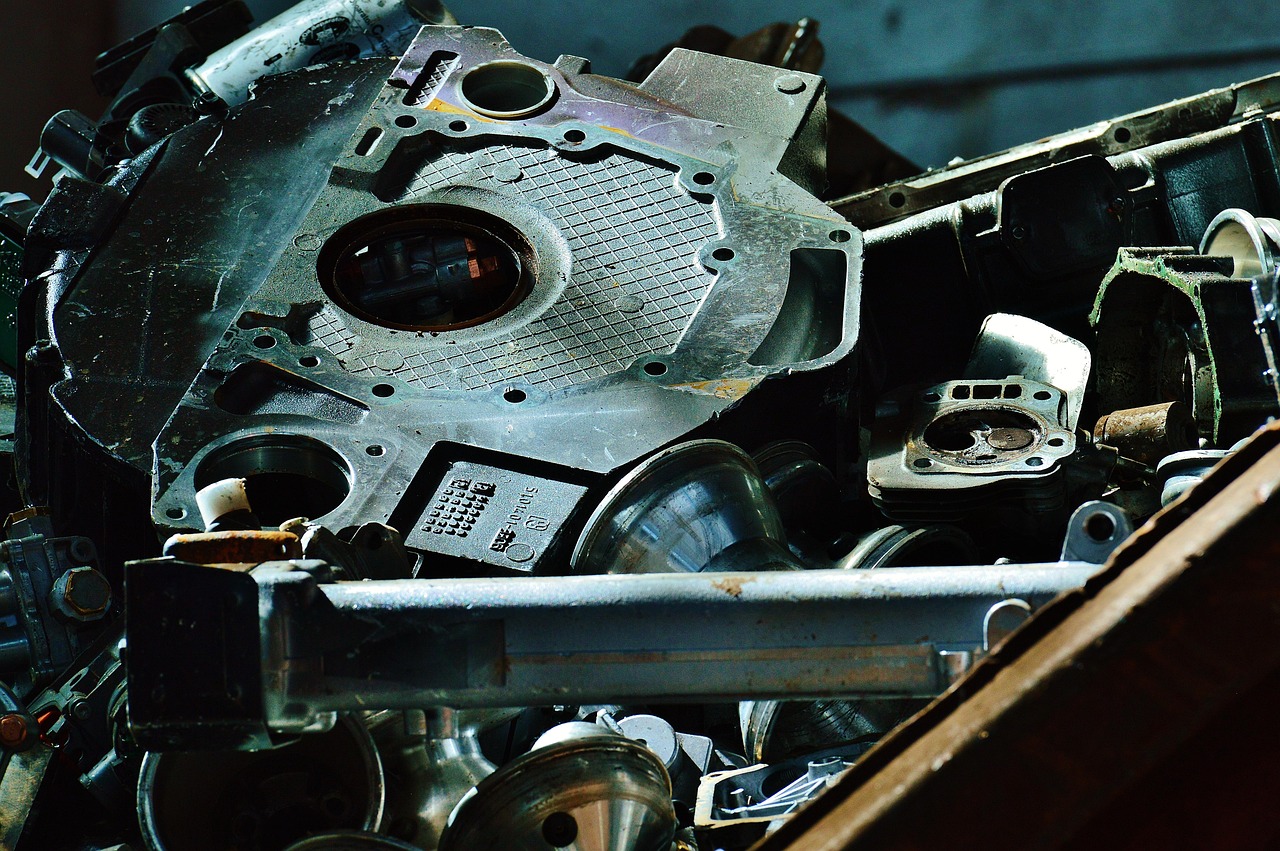

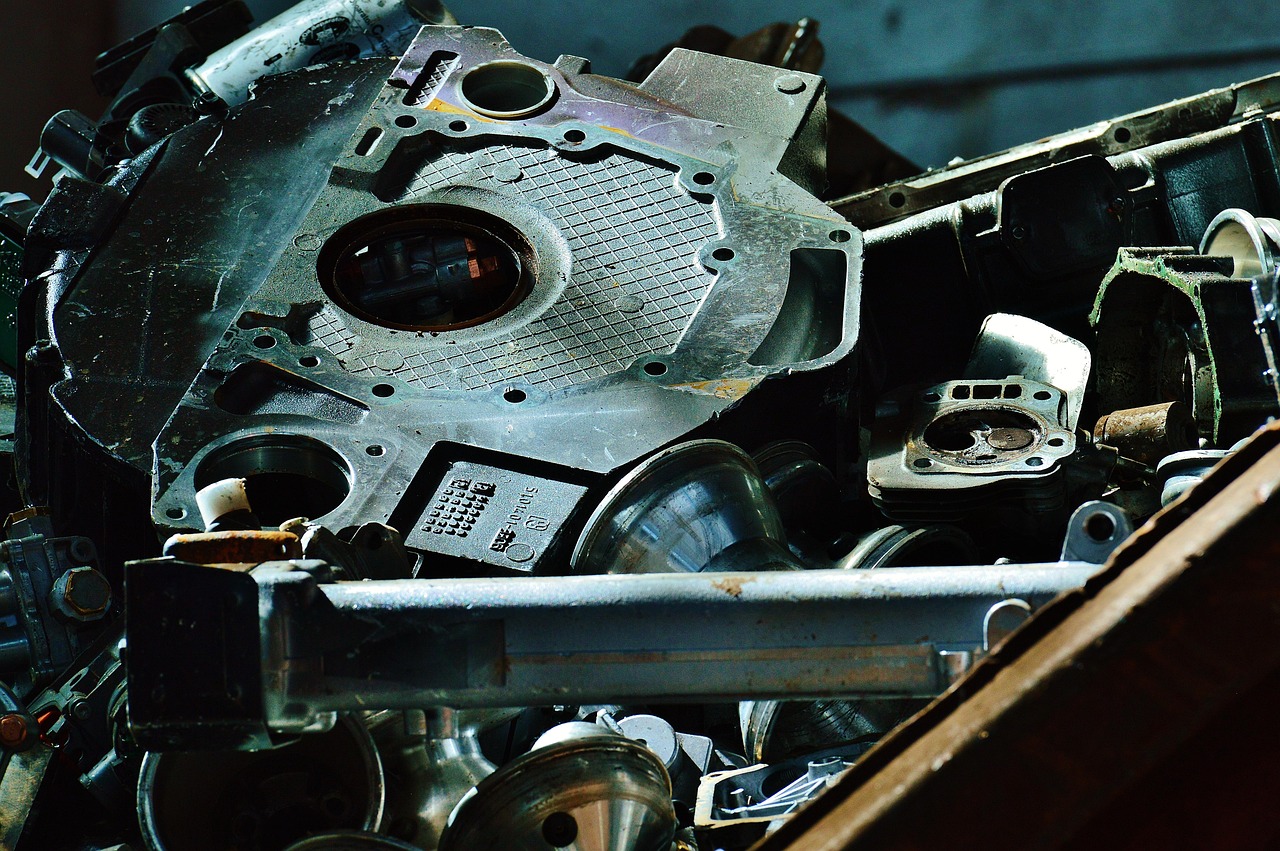

The NewtonX In-Line XRF Analyzer by Terra Scientific automates real-time, high-throughput quality control for metal production, mining, and coatings. It enables 24/7 elemental analysis (K to U, 1ppm–99.99%) with PASS/FAIL grading, replacing manual XRF in industries like automotive and aerospace. Integrated with production lines, it boosts efficiency, cuts costs, and ensures 100% inspection for metals, ores, and liquids—delivering instant results with remote data management.

Conclusion

X-ray analyzers are indispensable tools for non-destructive testing and analysis, providing valuable insights across industries like medicine, security, and manufacturing. When purchasing one online, it's essential to evaluate the type of analyzer you need, its features, and its suitability for your specific requirements. By understanding the technology behind these devices, you can make a more informed decision and find the best analyzer for your needs.

Join Us

Subscribe to our email list for updates & promotions.