Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

X-Ray Fluorescence: A Revolutionary Tool for Analyzing Microstructures-XRF technology

In recent years, scientific advancements have revolutionized the way we analyze materials, offering more accurate, non-destructive, and detailed insights. One of the most impactful innovations in material analysis is X-Ray Fluorescence (XRF) technology. This powerful tool has transformed the way researchers and industries assess microstructures, providing deeper insights into elemental composition and material properties. Let's dive into the core of XRF technology and how it’s reshaping the field of material science.

What is X-Ray Fluorescence (XRF)?

X-Ray Fluorescence is a non-destructive analytical technique used to determine the elemental composition of materials. It works by exposing a sample to high-energy X-rays, which excite atoms in the sample, causing them to emit fluorescent (secondary) X-rays. By measuring the energy and intensity of these emitted X-rays, scientists can identify the elements present in the sample and determine their concentrations.

XRF is used in a wide range of industries, including metallurgy, geology, archaeology, environmental science, and electronics, to name a few. Its ability to analyze both large and small samples without altering them makes it an invaluable tool for studying materials at the microstructural level.

How Does XRF Work?

The process of XRF is straightforward yet sophisticated. Here’s how it works:

Excitation: A sample is irradiated with high-energy X-rays. These X-rays have enough energy to knock electrons out of the inner shells of atoms in the sample.

Fluorescence Emission: When an atom's inner electron is ejected, the atom becomes unstable. To return to its stable state, an electron from an outer shell falls into the inner shell, releasing energy in the form of X-ray fluorescence.

Detection: The emitted X-rays are detected by a spectrometer, which measures the energy and intensity of the fluorescent X-rays.

Analysis: The energy levels of the emitted X-rays are characteristic of the elements present in the sample. By comparing these energies to known reference data, analysts can determine the elements and their concentrations.

This technique is incredibly valuable for identifying the elemental composition of materials without causing any harm or alteration to the sample, making it ideal for sensitive materials or objects like ancient artifacts or high-performance alloys.

Applications of XRF in Microstructure Analysis

XRF technology has a wide range of applications in microstructure analysis, which is crucial for industries that rely on the precise composition of materials. Some of the key areas where XRF excels include:

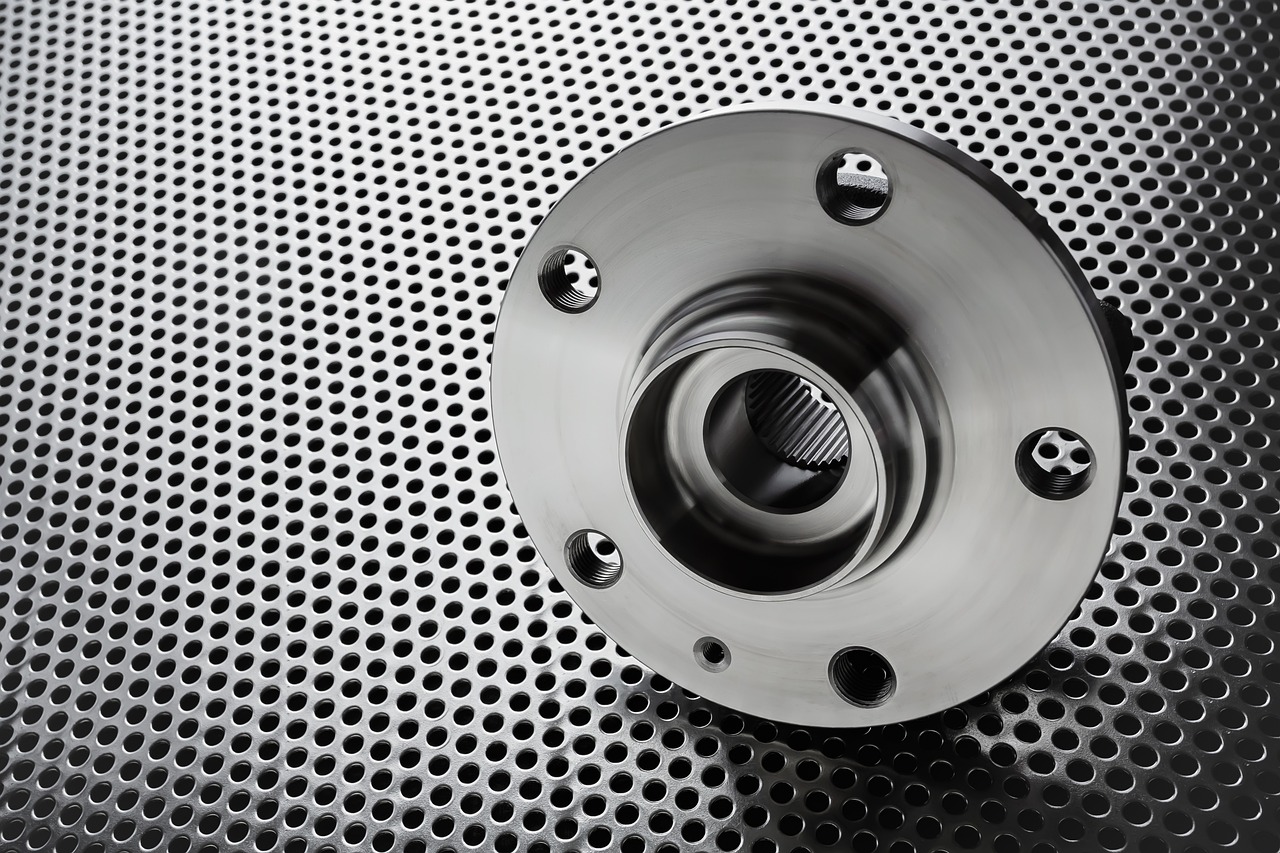

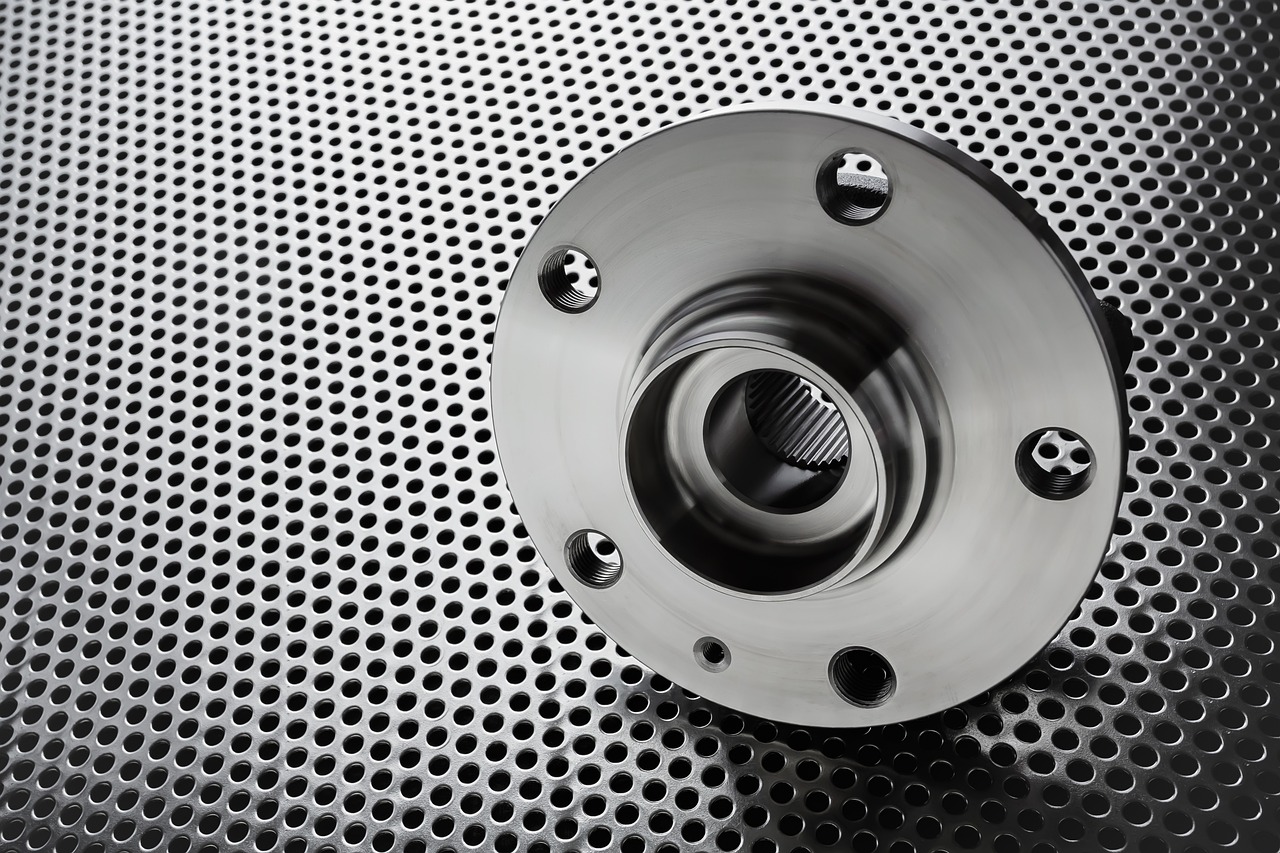

Metallurgy and Alloys:

XRF is extensively used in metallurgy to analyze alloys and metals. By determining the exact composition of an alloy, manufacturers can ensure that materials meet required specifications for strength, durability, and other performance characteristics. This is especially important in industries like aerospace, automotive, and construction, where the failure of materials can lead to catastrophic consequences.

Nanotechnology:

In the field of nanotechnology, where materials are often engineered at the atomic or molecular level, XRF is invaluable for analyzing and characterizing nanomaterials. Its ability to provide precise elemental analysis at micro levels allows researchers to understand how the arrangement of atoms impacts the properties of these materials.

Environmental Monitoring:

XRF plays a vital role in environmental science by detecting pollutants and contaminants in soil, water, and air. It can be used to assess heavy metals, like lead, mercury, and cadmium, in the environment. The ability to quickly and accurately measure trace elements makes XRF a powerful tool for environmental monitoring and remediation.

Archaeology:

Archaeologists use XRF to study ancient artifacts and materials without damaging them. XRF allows for the analysis of pottery, coins, metals, and other materials to determine their composition and origins, helping researchers piece together the history of ancient civilizations.

Semiconductor Industry:

XRF technology is crucial in the semiconductor industry for the analysis of thin films and microstructures used in microelectronics. By understanding the elemental composition of these materials, manufacturers can optimize their properties for use in the production of electronic components such as integrated circuits and sensors.

Advantages of XRF in Microstructure Analysis

The use of XRF for analyzing microstructures offers several distinct advantages:

Non-Destructive: One of the most significant benefits of XRF is that it does not damage or alter the sample. This is particularly important when dealing with valuable or rare materials that cannot be replaced.

High Sensitivity: XRF can detect elements present in trace amounts, down to parts per million (ppm), which is critical for applications where minute variations in composition can impact material performance.

Speed and Convenience: XRF provides rapid results, with analysis often taking only a few minutes. This makes it an efficient tool for routine testing, quality control, and large-scale material analysis.

Versatility: XRF can be used to analyze a wide variety of materials, from solids and liquids to powders and thin films. It is effective across many industries, providing a broad range of analytical possibilities.

Minimal Sample Preparation: XRF requires little to no sample preparation, which reduces time and cost. For most materials, the sample can be analyzed directly without the need for complex procedures.

Combining advanced FP algorithms with SDD/Si-Pin detection, the portable EulerX 900 provides nondestructive metal analysis in 1-2 seconds. The rugged, IP54-rated unit offers intuitive glove-compatible operation, tapered test head for complex geometries, and stores 100,000+ test results - perfect for PMI, recycling, and production control.

Terras EulerX900 Handheld Alloy Analyzer

Conclusion

X-Ray Fluorescence technology is a revolutionary tool that continues to make a significant impact across various industries, particularly in the realm of microstructure analysis. Its ability to provide fast, non-destructive, and highly accurate elemental analysis has made it an essential instrument in fields ranging from material science and archaeology to environmental monitoring and nanotechnology.

As advancements continue to refine XRF technology, it’s clear that this tool will only grow in importance. Researchers and industries that rely on precise material characterization will undoubtedly continue to benefit from the power and versatility of XRF in the years to come.

Join Us

Subscribe to our email list for updates & promotions.