Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

XRF Metal Analyzers in Quality Control: Ensuring Precise Metal Composition

Introduction

In industries where metal composition is critical—such as aerospace, automotive, construction, and manufacturing—quality control is non-negotiable. Even minor deviations in metal alloys can lead to structural failures, safety hazards, or costly recalls. This is where X-ray Fluorescence (XRF) metal analyzers play a pivotal role. These advanced instruments provide fast, accurate, and non-destructive testing of metal composition, ensuring compliance with industry standards and specifications.

In this blog, we’ll explore how XRF metal analyzers enhance quality control processes, their key benefits, and their applications across various industries.

What is XRF Technology?

XRF (X-ray Fluorescence) is an analytical technique used to determine the elemental composition of materials. When a metal sample is exposed to X-rays, its atoms emit secondary (fluorescent) X-rays unique to each element. The XRF analyzer detects these emissions and provides a detailed breakdown of the sample’s composition.

Types of XRF Metal Analyzers

Handheld XRF Analyzers – Portable devices ideal for on-site testing, scrap sorting, and in-process quality checks.

Benchtop XRF Analyzers – Higher precision instruments used in laboratories for detailed alloy verification and research.

Key Benefits of XRF Metal Analyzers in Quality Control

1. Non-Destructive Testing

Unlike traditional methods (such as acid testing or spark spectrometry), XRF does not damage the sample. This allows for repeated testing without material waste.

2. Fast and Accurate Results

XRF analyzers deliver results in seconds, enabling real-time decision-making in production lines, warehouses, and recycling facilities.

3. Compliance with Industry Standards

Industries such as aerospace (AMS, ASTM), automotive (ISO), and construction (EN) require strict adherence to material specifications. XRF ensures metals meet regulatory and customer requirements.

4. Detection of Impurities and Alloy Mix-Ups

XRF can identify trace elements and contaminants that may affect metal performance, preventing costly errors in manufacturing.

5. Cost-Effective Quality Assurance

By reducing lab testing time and minimizing material waste, XRF analyzers lower operational costs while improving quality control efficiency.

Applications of XRF in Various Industries

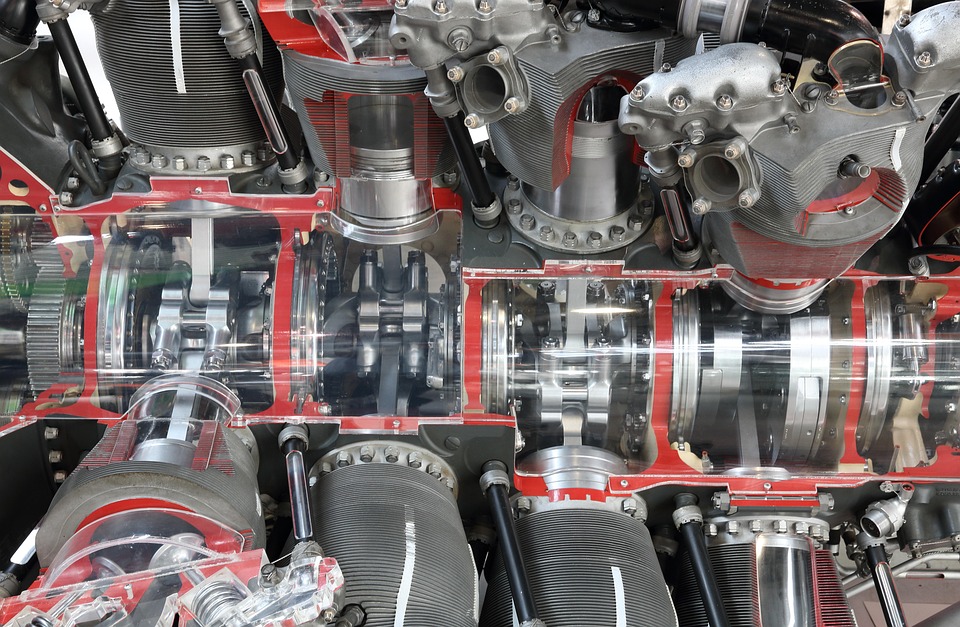

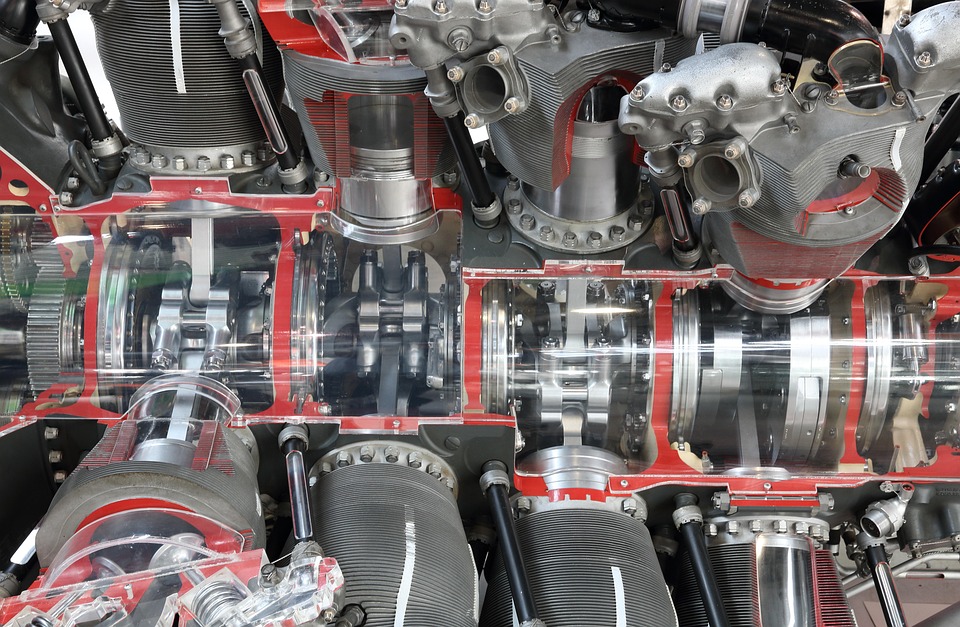

1. Aerospace & Defense

Verification of high-performance alloys (e.g., titanium, nickel-based superalloys)

Detection of counterfeit or substandard materials

2. Automotive Manufacturing

Ensuring correct alloy grades for engine components, exhaust systems, and safety parts

Preventing mix-ups in aluminum, steel, and magnesium alloys

3. Scrap Metal Recycling

Rapid sorting of ferrous and non-ferrous metals

Identifying hazardous elements (e.g., lead, cadmium) for safe recycling

4. Oil & Gas

Analysis of corrosion-resistant alloys in pipelines and valves

Quality checks on welding materials to prevent failures

5. Jewelry & Precious Metals

Authenticating gold, silver, and platinum content

Detecting counterfeit or under-karated jewelry

Choosing the Right XRF Analyzer for Your Needs

When selecting an XRF metal analyzer, consider:

Detection Range (light elements vs. heavy metals)

Portability (handheld vs. benchtop)

Regulatory Compliance (meeting industry-specific standards)

Software & Data Management (reporting and integration capabilities)

Terras EulerX900 Handheld Alloy Analyzer

EulerX 900 series handheld alloy analyzers offer fast, accurate, and non-destructive metal analysis. Ideal for alloy grade identification, quality control, and scrap metal recycling, it delivers lab-quality results within seconds. With an ergonomic design, long-lasting battery, and user-friendly interface, it operates anywhere with minimal training. The analyzer features a library of over 1600 alloy grades and can store up to 100,000 test results, making it an efficient tool for diverse metal analysis tasks.

Conclusion

XRF metal analyzers have revolutionized quality control by providing rapid, precise, and non-destructive metal composition analysis. From aerospace to scrap recycling, these devices ensure materials meet exact specifications, preventing defects and enhancing product reliability.

Investing in the right XRF technology not only improves quality assurance but also optimizes production efficiency and reduces costs. As industries continue to demand higher material integrity, XRF analyzers will remain an indispensable tool for maintaining excellence in metal manufacturing and processing.

Join Us

Subscribe to our email list for updates & promotions.